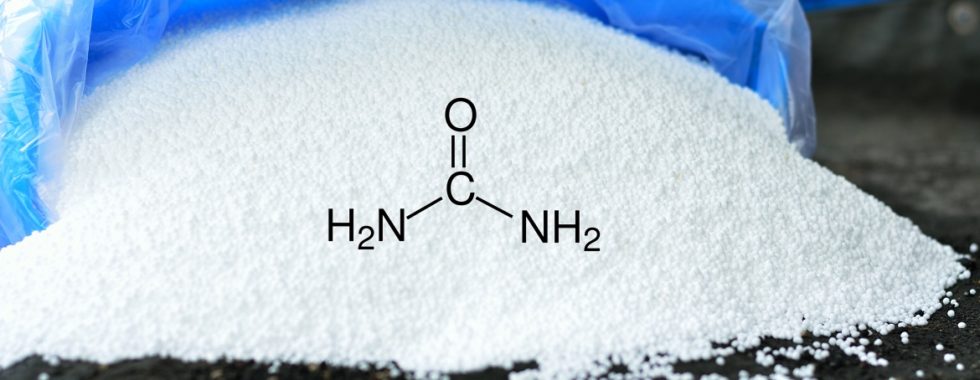

The most common method for producing urea is the Haber-Bosch process, named after its inventors Fritz Haber and Carl Bosch. Here’s a simplified breakdown of the process:

- Feedstock Preparation: Natural gas (methane, CH4) and atmospheric air are the primary feedstocks for urea production. The methane undergoes a process called steam reforming to produce a mixture of hydrogen (H2), carbon monoxide (CO), and carbon dioxide (CO2).

- Synthesis: The hydrogen and carbon monoxide from the reformed gas react under high pressure (around 150-300 atmospheres) and temperature (around 150-350°C) in the presence of a catalyst (usually iron-based) to form ammonia (NH3). This reaction is reversible, meaning it can go both ways.

- Conversion to Urea: The ammonia then reacts with carbon dioxide (CO2) in a separate step to form urea. This reaction also occurs under pressure and elevated temperature, typically with the use of a different catalyst.

- Purification and Prilling: The final product undergoes purification to remove impurities. Finally, the liquid urea is solidified into small, round pellets called prills for easier storage and transportation.

Manufacturing Companies in Iran

Iran has a significant urea production capacity, with several major players in the industry. Here are some key manufacturers:

- Shiraz Petrochemical Company: As you mentioned, Shiraz Petrochemical is the second-largest urea producer in Iran, boasting an annual production exceeding 1 million tons.

- Urmia Petrochemical Company: Located in West Azerbaijan Province, Urmia Petrochemical is another major producer with a significant annual urea output.

- Petrochemical Industries Development Company (PIDC): PIDC is a holding company that oversees various petrochemical complexes in Iran, including several with urea production capabilities.

- Zanjan Petrochemical Company: Situated in Zanjan Province, this company contributes to Iran’s overall urea production.

These are just a few examples, and Iran has several other companies involved in urea manufacturing.

Beyond Agriculture: Additional Applications of Urea

While agriculture remains the primary application of urea, it also finds uses in other sectors:

- Chemical Industry: Urea serves as a raw material for the production of various chemicals, including resins, plastics, and adhesives.

- Animal Feed Industry: Urea can be used as a protein supplement in animal feed, although its use is often regulated due to potential health concerns.

- Environmental Applications: Urea can be utilized in certain pollution control technologies, such as those aimed at reducing nitrogen oxide emissions from vehicles.

Conclusion

Urea plays a critical role in global food security by ensuring adequate nitrogen availability for crops. Iran, with its established production capacity and multiple manufacturing companies, is a significant contributor to the global supply of this essential agricultural input. As the demand for food continues to rise with a growing population, the production and responsible use of urea will remain crucial for sustainable agricultural practices.

Naftab company has the possibility of supplying urea produced in Iran for all export destinations in the world. Contact us to get the best sales offers info(at)naftab.ir